- Help Center

- Motor-CAD

-

Getting Started With Ansys

-

Ansys Installation

-

Licensing

-

Ansys Mechanical

-

ANSYS AEDT

-

Ansys Maxwell

-

Ansys HFSS

-

Ansys CFD

-

CAD

-

Meshing

-

LS-Dyna & LS-Prepost

-

SpaceClaim

-

Ensight

-

Ansys Lumerical

-

Zemax

-

Discovery

-

AUTODYN

-

Workbench

-

Ansys EMC Plus

-

SIwave

-

CFD-Post

-

Ansys Sherlock

-

Q3D

-

Ansys 3D Layout

-

Fluent Meshing

-

Thermal Desktop

-

Icepak

-

Ansys Icepak

-

Twin Builder

-

Fluent

-

AEDT Circuit

-

EMA3D

-

Linux

-

Optislang

-

Motor-CAD

-

Ansys CFX

How to enable AC winding losses in Motor-CAD simulation?

Accurately calculating these AC winding losses is essential for precise efficiency prediction and thermal performance estimation in electric motor design.

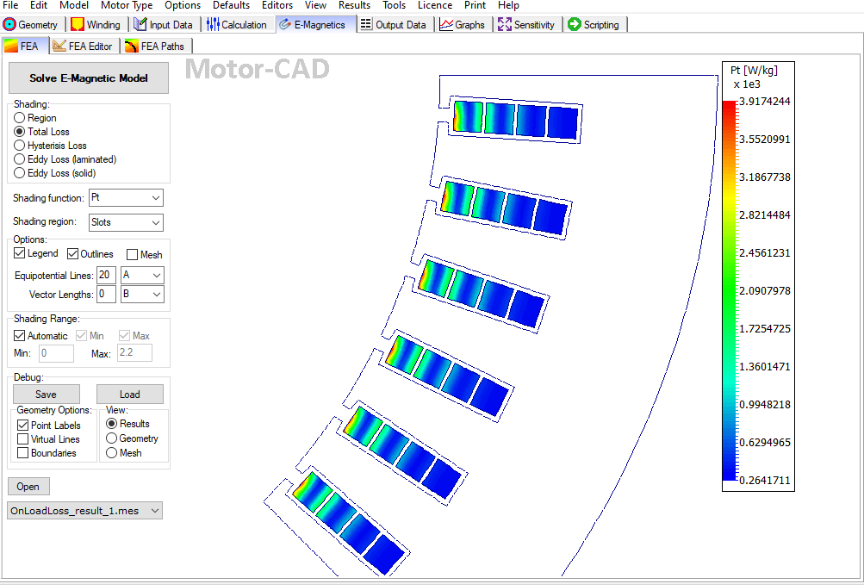

To calculate the AC losses in Motor-CAD, there are three ways to do it.

- Hybrid FEA Method

This method calculates AC winding losses using the electromagnetic model with a hybrid analytical–FEA approach.

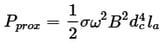

- Proximity losses are derived from the local flux density (B) in each slot region, sampled from FEA results.

- For Litz wire, losses are evenly distributed among conductors (due to twisting).

- Skin effect correction reduces losses when the skin depth (δ) is smaller than the conductor height or diameter.

Key equations:

- Proximity loss (round conductor):

- Skin-effect loss:

Calibration is typically needed for multi-strand or hairpin windings, since they have complex eddy-current interactions.

2. Full FEA (Single Slot)This method performs a detailed electromagnetic finite-element simulation on a single representative slot rather than the full motor.

- It computes eddy current and proximity effects within that slot to obtain an accurate local AC loss distribution.

- This approach balances accuracy and computational speed—ideal for calibration or comparison with the Hybrid FEA model.

It is often used to validate or fine-tune the hybrid model’s assumptions before switching to full-machine analysis.

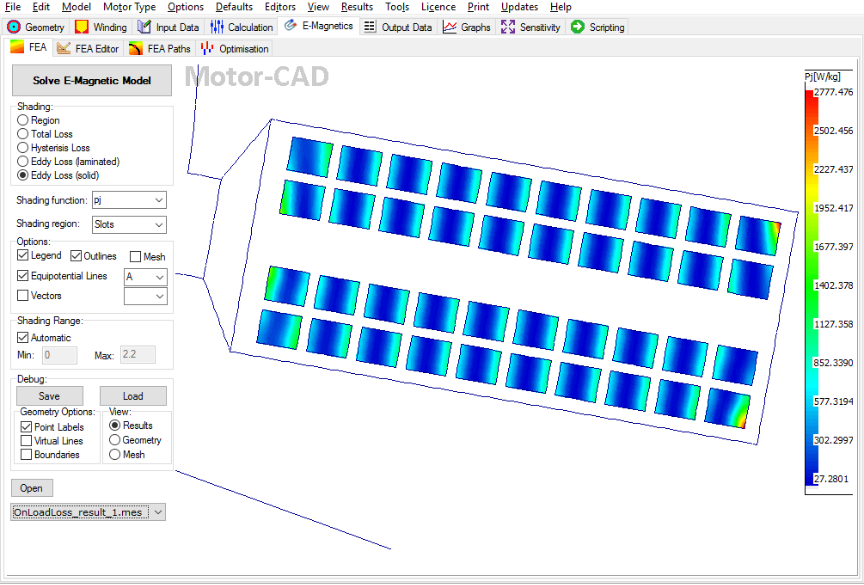

This is the most accurate AC winding loss method, simulating all stator slots populated with conductors in the full electromagnetic model.

- It fully captures mutual eddy-current coupling between slots and global magnetic interactions, ensuring balanced solutions for torque, power, and iron loss.

- Greatly increases computational time but provides true loss distribution across the entire winding.

- The Bundle Aspect Ratio parameter can be adjusted to explore conductor placement effects on AC losses (e.g., wide vs. deep conductor layouts).

To enable one of the AC winding loss calculation methods based on your requirements, follow the steps shown in the screenshot below within the Motor-CAD interface.

-2.png?height=120&name=Ozen%20Long%20-%20Back%20(1)-2.png)